Machine stirring-type desulfurization facilities (KR facilities)

Summary

I let you immerse an impeller in melted pig iron with facilities called KR and stir melted pig iron by turning it and usually remove impurities.

It is the technique that there was from the first that melted pig iron spare processing was developed as desulfurization processing, but, by us's original know-how and research and development, I accomplish further evolution, and high desulfurization is possible.

It is the technique that there was from the first that melted pig iron spare processing was developed as desulfurization processing, but, by us's original know-how and research and development, I accomplish further evolution, and high desulfurization is possible.

Features

- Realization of was stable, deep, desulfurizing it

The roller restriction method of the carriage adopts a spring expression.

The going up and down of the carriage of the inside to stir at high speed (turn) is possible while holding down a vibration level.

In addition, the desulfurization agent injection adopts Blasting method.

By these, stable deep desulfurization is possible.

- Reduction in cost & environment measures

In comparison with an addition method, the basic unit reduction of around 30% of desulfurizations agent is enabled by adopting Blasting method in the desulfurization agent injection (of that of the conventional company products)

In this way, little operation of the environmental load by reduction in cost by the desulfurization agent consumption decrease and the quantity of slag generating decrease is enabled.

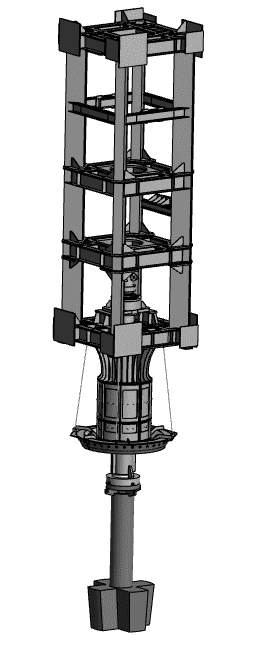

KR carriage 3D model

Impeller―

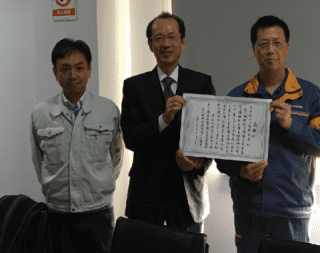

The KR appearance

In 2019, we delivered KR equipment to Baoshan Iron & Steel.

We received a certificate of commendation for contributing to stable operation, cost reduction, and reduction of environmental load.

We received a certificate of commendation for contributing to stable operation, cost reduction, and reduction of environmental load.

Delivery record

43 equipment in Japan and overseas (by April 2021)